| English | Select | |

| 한국어 | Select | |

| Русский | Select |

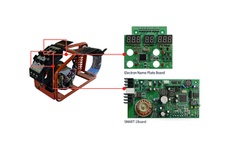

ONE-TOUCH METHOD OF INTEGRAL STRUCTURE

Force cooling method by CO2 Gas (64 Saturation)

Reduced cost of purchase

50% reduction in adapter replacement cost

Reduced repair costs

50% reduction in adapter replacement cost

Reduced cost due to recruitment

Reduced failure rate, shortened maintenance time, shortened work preparation, etc. Minimizing operational cost

3-WAY METHOD OF SEPARATING STRUCTURE

Natural cooling method by atmosphere temperature (84 Saturation)

A typical power-power power adapter expands the tightening portion of the engagement by increasing the temperature of the temperature by 84 degrees Celsius. There are many issues that are not isolated after the operation. This is a normal process for creating a pre-qualifying, pre-qualifying grinder in the printer, and the finely fabricated power adapter becomes loose, resulting in more heat generation and deformation, resulting in a replacement. Using an all-in-one adapter produces a forced cooling effect of internal CO2 gases and reduces the effectiveness of CO2 in winter with its own heating effects.

SPECIFICATION

| division | common purpose adapter | all-in-one adapter | note |

|---|---|---|---|

| adapter terminal time | 60min | 10min | Reduce repair time |

| cooling system | natural air cooling | forced air-cooled | prevention of deterioration |

| terminal type image | fork type structure | linear structure | failure rate reduction |

| terminal processing length | 1~2M | within10Cm | reduce repair materials |

| fastening system | step 3 Individually Tightening | one-step engagement | improve working conditions |